| Cabin | | Right rudder/half row |

| Whole vehicle main dimensions | Overall dimensions (LxWxH)mm | 8905×2460×2820 |

| Wheel base(mm) | 5150 |

| Weight data | Curb weight(kg) | 5470 |

| Gross vehicle weight(kg) | 22000 |

| Persons in cab (persons) | 2 |

| Engine | Model | YC6A240-33 |

| Emissions standards | Euro III |

| Displacement(L) | 7.255L |

| Rated Power | 177 |

| Max torque | 900 |

| Gearbox | Model | 8JS105TA |

| Clutch | Type | Single dry diaphragm spring |

| Front axle | Type | 5.5.T |

| Rear axle | Type/Mainreducetion ratio | 10T/4.875 |

| Suspension | Front suspension/Leaf spring number | Non-independent suspension longitudinal plate spring /10 |

| Rear suspension/Leaf spring number | Non-independent suspension longitudinal plate spring /10+8 |

| Brake system | Service brake | Drum-type pneumatic brake |

| Parking brake | Barely able to brake |

| Crane parameters | Crane specifications | SQ(4-6)SK3Q |

| Maximum lifting weight (T) | 6 |

| Maximum lifting moment (T.M) | 12.5 |

| Maximum working range (MM) | 11000 |

| Maximum working height (MM) | 13000 |

| Crane weight (kg) | 2215 |

| Rotation range | 360° full rotation |

| PTO | Foton Overseas is responsible for the installation of power take-offs |

| Cargo box | Container internal dimensions | 7500×2500×600(mm)Outside size |

| (Length×Width×Height) | |

| Side board | Side board structure: corrugated board, can be turned down to open, 3 doors on each side |

| Each side board uses three hinges to connect with the bottom board, and the column is detachabl |

| Side board thickness: 1.5mm |

| foreboard | Front panel structure: corrugated board with gantry |

| Front plate height: the height of the front plate and the cab |

| Bottom plate | Floor structure: checkered steel plateFloor thickness: 3mm |

| Floor longitudinal beam: 14# channel steel |

| Floor beam: The beam is 10# channel steel, and the distance between the floor beams is 300mm |

| Subframe | Subframe material: Q345B manganese steel |

| back door | Back door structure: corrugated board, can be turned down |

| Process requirements | Welding requirements | Adopt ternary gas shielded welding; to ensure that the welding seam is uniform and smooth, the welding is firm and reliable, and there should be no cracks, slag inclusions, weld penetration, and weld leakage. |

| Painting requirements | Pre-painting treatment: polishing and rust removal before painting; |

| Glue requirements | The front panel, the welded part, the side lamp frame, the bottom plate connection, etc. need to be treated with sealant |

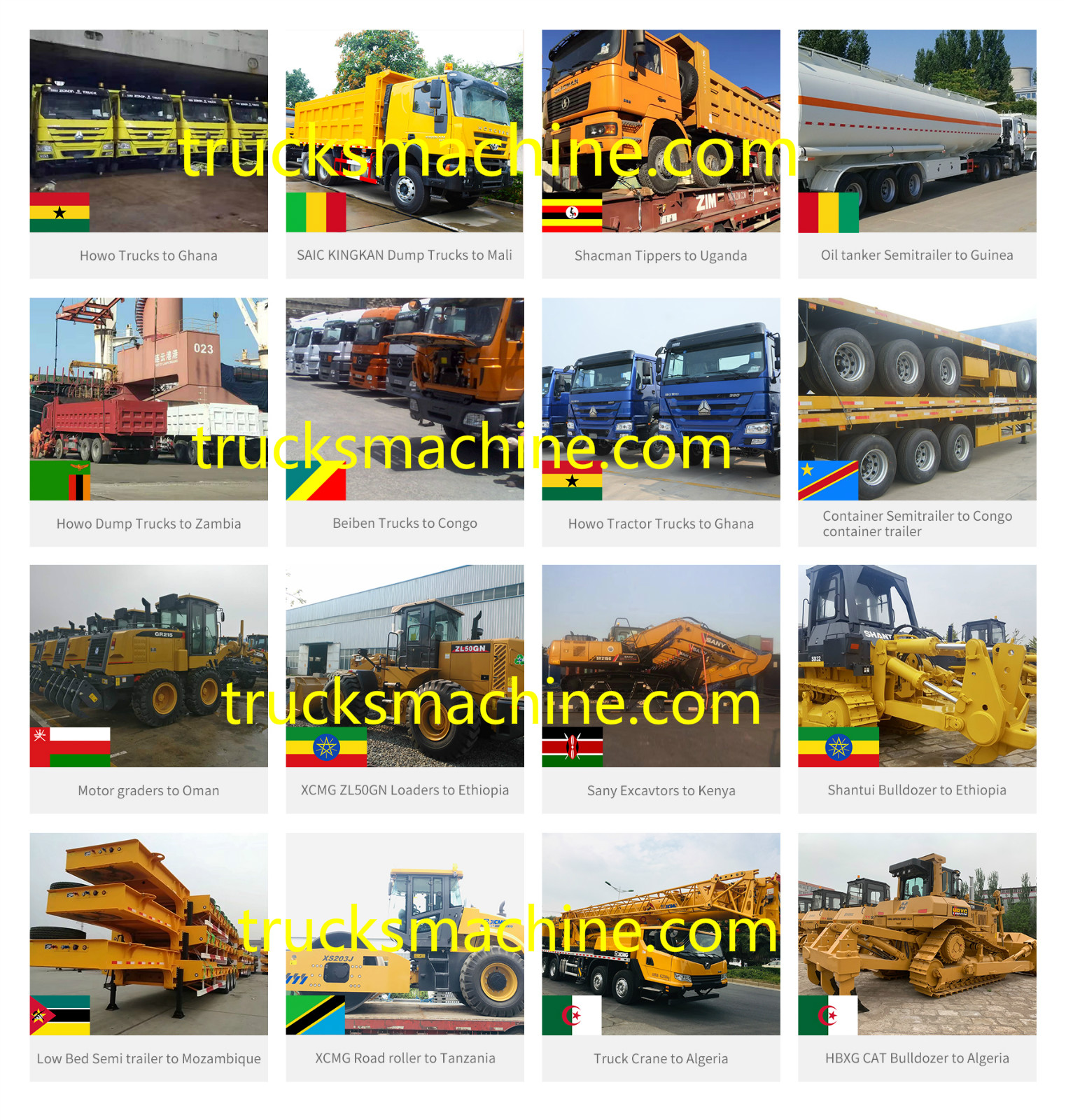

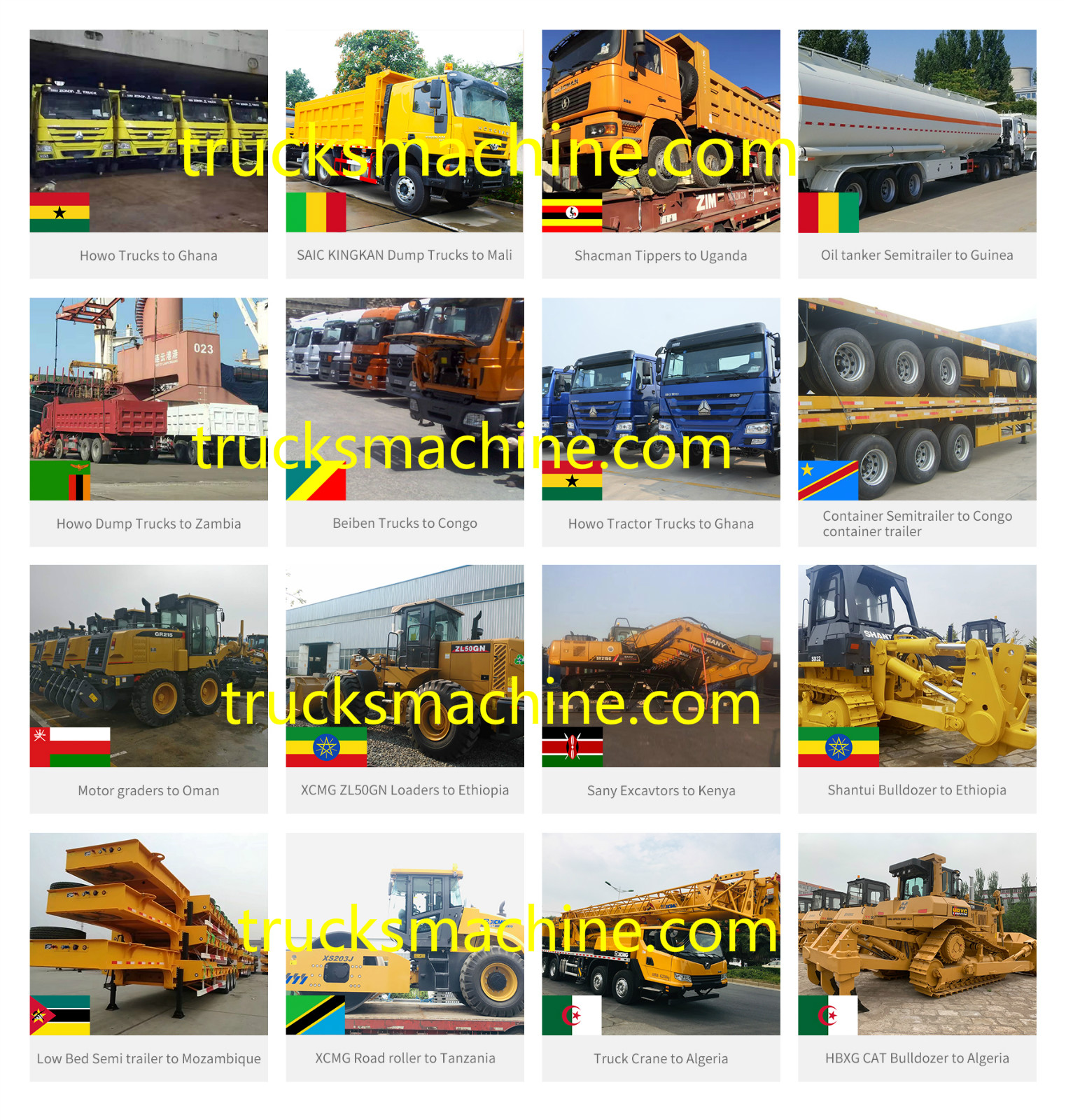

Tourfine the Best Trucks and Machinery Supplier

Tourfine the Best Trucks and Machinery Supplier

WeChat

Scan the QR Code with wechat